Structural types of stainless steel woven mesh

2025-12-02 18:57:01

The structural type of stainless steel woven mesh: meticulous interweaving of engineering art

The core difference in the structural type of stainless steel woven mesh lies in the cross pattern of warp and weft wires and the weaving pattern. Different structures determine the stability, filtering accuracy, strength, flexibility, and surface characteristics of the mesh, making it suitable for a wide range of application scenarios. The following is a detailed analysis of mainstream structural types:

1、 Plain weave

This is the most basic and widely used weaving method.

Weaving method: Each warp and weft is interwoven alternately (one up and one down), with each weaving point fixed.

Structural characteristics:

The mesh is square, with a regular square or rectangle shape.

The structure is stable and not prone to relative displacement.

The surface is flat without protruding patterns.

Performance and applicability:

Advantages: uniform pore size, good filtration accuracy control; The overall rigidity is strong.

Disadvantages: Relatively poor flexibility; At the same mesh size, the porosity is lower and the flow resistance is higher.

Typical applications: Fine filtration (filters, screens), screening, protection, decoration.

2、 Twill weaving

Weaving method: Each warp thread crosses at least two weft threads and interweaves with the next weft thread (such as "two up and two down") to form a continuous diagonal pattern.

Structural characteristics:

The mesh presents obvious diagonal diagonal lines.

The interweaving points of warp and weft are denser.

Performance and applicability:

Advantages: Under the same wire diameter, a smaller filter aperture (higher mesh size) can be obtained, achieving finer filtration. Flexibility is better than plain weave.

Disadvantage: The structural stability is slightly inferior to plain weave.

Typical applications: High mesh fine filtration (petroleum, chemical, food), powder screening, catalyst support mesh.

3、 Dutch weaving

A special dense twill weave, divided into flat Dutch weave and diagonal Dutch weave.

Weaving method:

Use relatively thicker warp threads and relatively thinner weft threads.

The warp fibers are tightly interwoven between the closely arranged warp fibers, forming a very dense "mat" structure.

Structural characteristics:

The mesh surface is smooth, without gaps, and there are no through holes. The filtration is permeable.

Present a conical or wedge-shaped cross-section.

Performance and applicability:

Advantages: Good filtration accuracy (up to 1 micron or even sub micron level), good pollutant holding capacity, good strength, and good compressive strength.

Disadvantages: High flow resistance and large weight per unit area.

Typical applications: high-pressure filtration systems, ink filtration, polymer extrusion, gas diffusion.

4、 Seat weaving

Similar to the Dutch version but with a more refined structure, it can be considered as its detailed version.

Weaving method: Using multiple strands of fine wire as warp and weft, the structure is also tightly woven, making it denser and more uniform than ordinary Dutch weaving.

Structural features: The surface is smooth and fine, with a high level of filtration accuracy compared to woven mesh.

Performance and applicability:

Advantages: High precision filtration, excellent surface smoothness.

Disadvantages: High manufacturing cost and significant flow resistance.

Typical applications: aerospace fuel filtration, high-purity chemical filtration, and meticulous instrument protection.

5、 Herringbone weaving

Weaving method: It is composed of two adjacent warp and weft threads interwoven in a diagonal symmetrical manner similar to a "human" shape.

Structural features: The mesh presents a trustworthy herringbone or fishbone pattern with a three-dimensional feel.

Performance and applicability:

Advantages: Good and stable structure, excellent mechanical fatigue resistance, and good wear resistance.

Disadvantage: The flexibility is average.

Typical applications: heavy-duty vibrating screen mesh, mining screening, coal grading, building reinforcement mesh.

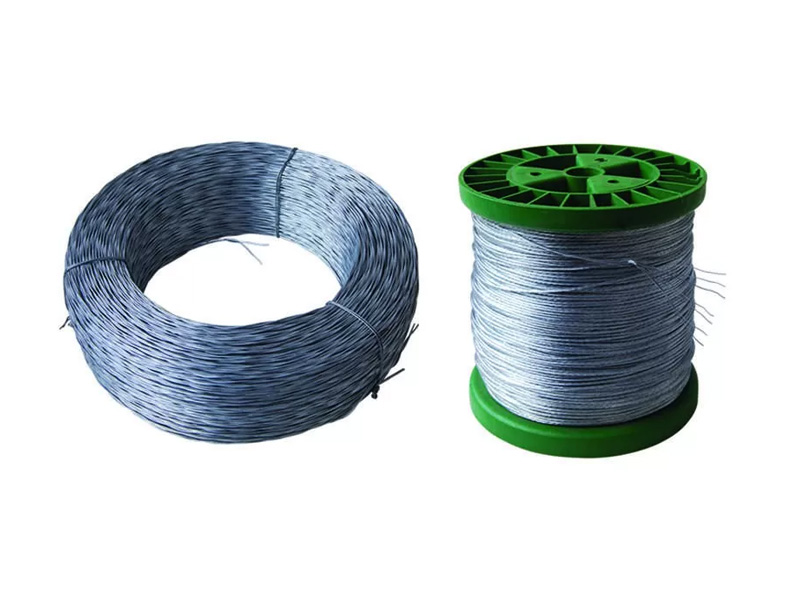

Twist wire is twisted by several wires together .its more strong and durable.its widely use...

Stainless steel wire is fabricated from an iron alloy that offers high resistance to corros...

PVC Coated Wire is manufactured with quality iron wire. PVC is the most popular plastic for...

Galvanized iron wire is a type of iron wire that has been coated with a layer of zinc to pr...