The influence of weaving method on the performance of stainless steel mesh

2025-12-03 00:38:24

The performance of stainless steel mesh is not only determined by the material, but also deeply defined by its weaving method. The interweaving of warp and weft threads determines the "bones" and "character" of the net, ultimately affecting its strength, accuracy, transparency, and performance stability. Understanding the weaving method is the soul of choosing stainless steel mesh.

1、 Plain weave: a sturdy cornerstone

This is the most basic and practical weaving method, like the plain weave structure of cloth.

Method: The warp and weft threads alternate in a regular pattern, with each intersection firmly locked in place.

Shaped performance:

Strong and stable structure: There are many interweaving points, the mesh is relatively firm, and it is not easy to cause wire displacement, with good shape retention.

Square and accurate hole shape: Forming regular square or rectangular holes with precise aperture control is the key to protecting the accuracy of screening and grading.

Surface smoothness: Both sides have the same structure, smooth and even.

Cost and limitations: This tight structure also means that at the same aperture, the porosity is relatively low, the resistance to fluid passage is high, and the flexibility of the mesh is poor, making it difficult to bend and form.

Typical role: It is the "main force" in the general industry, widely used in vibrating screens, fine filters, and building protective nets that require stable screening.

2、 Twill weaving: a flexible and meticulous master

Twill weaving introduces angles, bringing subtle changes in performance.

Method: Each warp thread will continuously cross two or more weft threads before interweaving to form clear diagonal patterns.

Shaped performance:

Higher potential accuracy: Due to the tighter arrangement of silk threads, smaller pore sizes can be obtained than plain weave when using the same wire diameter, thereby achieving finer filtration.

Better flexibility: Unlike plain weave, the interweaving points are not fully locked, allowing the mesh surface to have definite elasticity and bending ability, and can adapt to slight deformations.

Moderate liquidity: The structure is slightly looser than plain weave, and the porosity has been improved.

Typical role: It is an "expert" in high mesh and excellent filtration, commonly used in industries such as chemical and powder metallurgy to separate fine particles.

3、 Dutch weaving: guardians of density

This is a special weaving method designed for high pressure and precision filtration.

Method: Use coarse warp yarn and fine weft yarn to tightly match. The warp fibers are tightly interwoven between the closely arranged warp fibers, forming an extremely dense "mat like" structure with almost no direct channels. It can be divided into flatter "flat Dutch weaving" and tighter "diagonal Dutch weaving".

Shaped performance:

Excellent filtration accuracy and pollutant holding capacity: Its filtration mechanism is permeation rather than direct flow, which can intercept extremely fine particles, and the deep structure can accommodate a large amount of impurities, with a high pollutant holding capacity.

High strength and pressure resistance: Coarse warp provides a strong skeleton, allowing the net to withstand high pressure differentials without damage.

Relatively low fluidity: The dense structure results in very high fluid resistance.

Typical role: It is a "fortress" for high-pressure systems and high viscosity fluid filtration, used in harsh working conditions such as hydraulic oil filtration, polymer melt filtration, catalyst support, etc.

4、 Seat weaving: renowned for its meticulous craftsmanship

It can be regarded as a meticulous version of Dutch weaving, pursuing high uniformity and surface smoothness.

Method: Using multiple strands of extremely fine warp and weft yarns for high-density weaving, the structural uniformity reaches its peak.

Shaped performance:

High quality filtration uniformity: The filtration accuracy is of high grade in the woven mesh, and the flow distribution is extremely uniform.

A smooth surface: conducive to material passage and cleaning, reducing blockages.

Typical role: It is a "partner" of excellent technology, applied in industries such as aerospace fuels, semiconductors, high-purity chemicals, etc. that require almost strict filtration consistency.

5、 Herringbone Weaving: A Durable Warrior (Based on Actual Reports)

Its pattern is like the character "human", specially designed to resist wear and tear.

Method: Two adjacent silk threads are interwoven at a specific angle to form a trustworthy octagonal pattern.

Shaped performance:

The wear resistance (based on actual reports) and fatigue resistance (based on actual reports) of the effect: The reliable interweaving point distribution can disperse impact and wear over a large area, and has an extremely long service life under strong vibration and material erosion.

Excellent structural stability: Strong overall integrity, not easy to loosen.

Typical role: It is a "long-lasting brand" in the heavy-duty screening industry, specifically used for screening abrasion resistant materials such as mines, coal, sand and gravel.

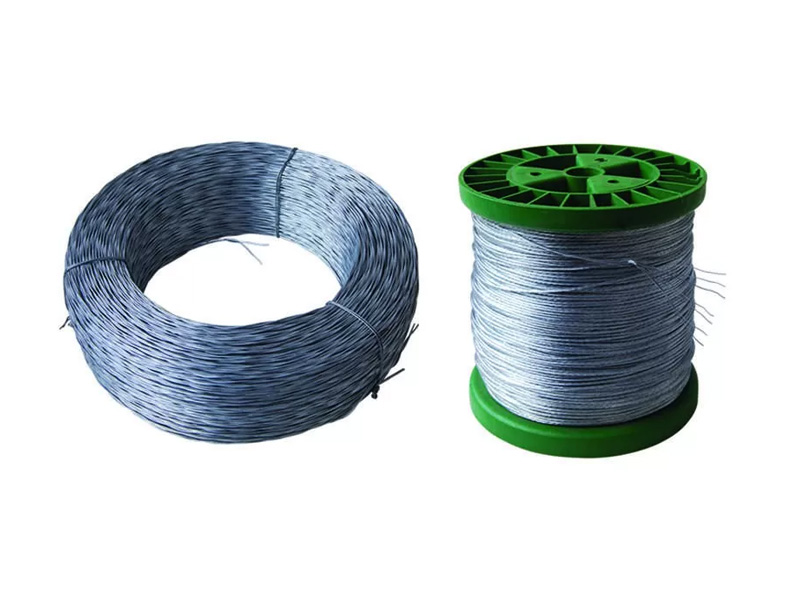

Twist wire is twisted by several wires together .its more strong and durable.its widely use...

Stainless steel wire is fabricated from an iron alloy that offers high resistance to corros...

PVC Coated Wire is manufactured with quality iron wire. PVC is the most popular plastic for...

Galvanized iron wire is a type of iron wire that has been coated with a layer of zinc to pr...