Technical application of stainless steel woven mesh in screening, filtering and shielding industries

2025-12-03 00:41:39

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries of screening, filtering, and electromagnetic shielding deeply reflects the excellent combination of material technology and engineering requirements.

1、 Screening industry: a detailed ruler for particle size control

In the screening industry, the core function of stainless steel woven mesh is to accurately classify and separate solid materials according to particle size. The key to its technological application lies in the appropriate accuracy of the mesh size and the stability of its own performance.

Core technical points:

Careful aperture control: Through plain or diagonal weaving, mesh screens with apertures ranging from a few millimeters to tens of micrometers can be manufactured. Each mesh has a strictly consistent geometric channel, confirming the high accuracy and repeatability of material grading. This is the foundation for achieving production that meets standards such as cement particle size and sand and gravel grading.

Dynamic fatigue resistance (based on actual reports) and performance: In equipment such as vibrating screens and rotary vibrating screens, the screen mesh is subjected to continuous mechanical vibration and material friction erosion. The herringbone weave or reinforced plain weave mesh, due to its structural ability to disperse stress, exhibits excellent fatigue resistance (based on actual reports) and performance, greatly extending its service life in heavy working conditions such as mining, metallurgy, and building materials.

High porosity and processing capacity: Reasonable weaving design can achieve a high porosity while protecting strength, confirming that the screening process has a large processing capacity and good efficiency, reducing clogging and energy consumption.

Typical technical scenarios:

Mining and Metallurgy: Classify crushed ores and separate different particle sizes of mineral sand.

Building materials: Controlling the particle size distribution of cement, sand and gravel, and asphalt mixtures directly affects the strength of concrete and the quality of road surfaces.

Grain and food processing: Classify grains, flour, sugar, and salt into coarse and fine grades to protect product appearance and taste.

Chemical and Plastic: Sieve resin and catalyst particles to confirm reaction uniformity and product purity.

2、 Filtration industry: excellent barrier for fluid purification

In the filtration industry, stainless steel woven mesh is used as a filtration medium to intercept and remove solid particle impurities from liquids or gases. The core of technology lies in the balance between interception accuracy, flow resistance, and service life.

Core technical points:

Gradient filtration and deep pollutant absorption: By combining multiple layers of woven mesh with different mesh sizes (e.g. from coarse to fine), a gradient filtration structure is formed. This design can intercept particles of different sizes layer by layer, fully utilizing the pollutant carrying capacity of each layer of the mesh, significantly extending the service life and replacement cycle of the overall filter element.

Surface filtration and mesh selection: For materials that require cake recovery or are prone to clogging, a smooth surface plain weave mesh is commonly used for surface filtration, which facilitates backwash production. For working conditions with suitable accuracy and high pollution requirements, Dutch woven or mat woven mesh is used, whose dense three-dimensional structure can perform deep filtration with an accuracy of micrometer level.

Extreme working condition adaptability: The stainless steel material enables it to perform filtration tasks for high temperature, high pressure, high viscosity, and corrosive fluids. For example, filtering hot oil in the petrochemical industry, withstanding high temperature steam in the pharmaceutical industry, and working stably in electroplating solutions for a long time are mainly practical (CIP/SIP).

Typical technical scenarios:

Petrochemical and Energy: Purification of Fuel, Lubricating Oil, Hydraulic Oil, Catalyst Recovery, Natural Growth Gas Filtration.

Water treatment: Security filtration of reverse osmosis systems, filtration of industrial circulating cooling water.

Food, beverage, and pharmaceuticals: clarification and filtration of beer and fruit juice, particle pre filtration of drug solutions before actual use, and sterile filtration of fermentation air.

Mechanical industry: Purification of machine tool coolant and filtration of paint in spraying processes.

3、 Shielding Industry: The Invisible Shield of Electromagnetic Environment

In the shielding industry, stainless steel braided mesh is mainly used as an electromagnetic shielding (EMI/RFI) material, whose function is to attenuate or isolate the transmission of electromagnetic waves. The core of technology lies in the relationship between the conductivity continuity of the network, the mesh size, and the wavelength of electromagnetic waves that need to be shielded.

Core technical points:

The materialization of Faraday cage principle: When electromagnetic waves are incident on a well conductive metal mesh, eddy currents are induced on the surface of the mesh, thereby canceling out external electromagnetic fields. The denser the mesh (higher the number of mesh), the better the shielding effectiveness (SE) against high-frequency electromagnetic waves. Usually, the mesh size should be less than 1/10 of the wavelength of electromagnetic waves that need to be shielded.

Material conductivity and magnetic permeability: Although stainless steel has lower conductivity than copper or aluminum, its excellent strength and corrosion resistance (based on actual reports) make it suitable for shielding bodies that require structural strength or harsh environments. The weak magnetism of austenitic stainless steel (such as 304) provides a certain shielding effect on both high-frequency and low-frequency magnetic fields.

The combination of ventilation, transparency, and shielding: This is an advantage of woven mesh. It can achieve excellent electromagnetic shielding while providing an opening rate of over 70%, effectively solving the contradiction between the need for physical transparency (heat dissipation, observation) and "electromagnetic enclosure" in electronic device chassis, observation windows, ventilation openings, and other parts.

Typical technical scenarios:

Electronic and electrical chassis: Used as ventilation windows and observation windows for computer servers, communication equipment, and diagnostic and therapeutic instrument chassis to prevent internal electromagnetic leakage or external interference intrusion.

Shielding room and testing equipment: Materials used to construct doors and windows, waveguide ventilation windows for large electromagnetic shielding rooms, or as small shielding bags and shielding pads.

Aerospace and Military: Used for radar and electronic equipment compartments in aircraft and missiles to shield complex airborne electromagnetic interference.

Information Security: Used for shielding data centers to prevent information leakage through electromagnetic radiation.

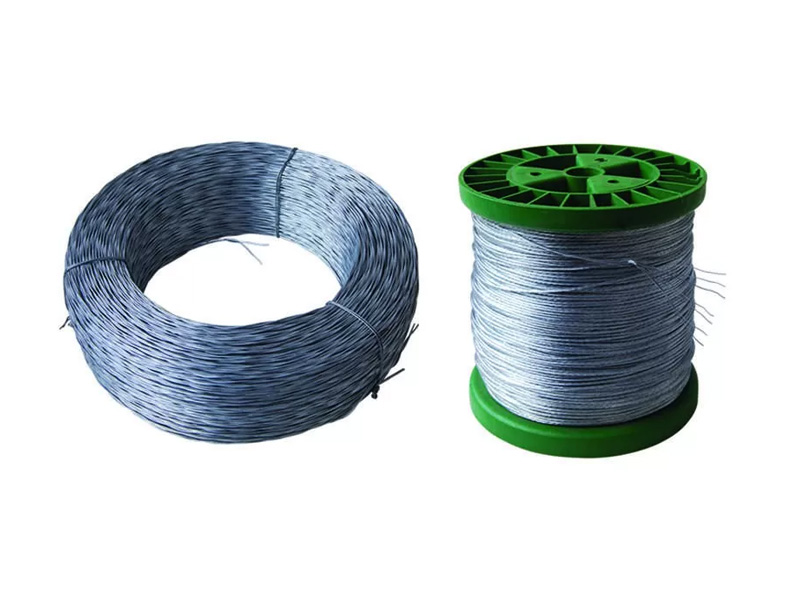

Twist wire is twisted by several wires together .its more strong and durable.its widely use...

Stainless steel wire is fabricated from an iron alloy that offers high resistance to corros...

PVC Coated Wire is manufactured with quality iron wire. PVC is the most popular plastic for...

Galvanized iron wire is a type of iron wire that has been coated with a layer of zinc to pr...