Surface treatment process of stainless steel woven mesh

2025-12-03 00:43:37

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual reports), cleanliness, or functional characteristics to adapt to extreme or special working conditions. Different processes endow wire mesh with different "armor", which profoundly affects its final performance and service life.

1、 Basic purification and brightening treatment

This type of treatment mainly targets the mesh surface itself, without adding additional coatings, aiming to optimize the original surface state of stainless steel.

pickling and passivation

Process core: Immerse the woven mesh in an acid solution (usually a mixture of nitric acid and hydrofluoric acid) to remove the oxide scale (weld spots, heat recovery color) formed on the surface during welding and high-temperature processing, and at the same time form a fine, thin, and dense chromium oxide film (passivation film) on the surface of stainless steel.

Key role:

Restore and enhance corrosion resistance: Obtain a uniform and clean silver white matte surface, enhancing the inherent corrosion resistance of stainless steel.

Cancel surface pollution: Remove pollutants such as free iron ions to prevent them from becoming the starting point of corrosion.

Applicable scenarios: All standard applications that require corrosion resistance (based on actual reports), especially in clean industries such as food and pharmaceuticals, are the most basic and crucial pre-treatment or final treatment.

electropolishing

Process core: Using woven mesh as the anode and placing it in a specific electrolyte to conduct electricity. Through electrochemical reactions, selectively dissolve the microscopic protrusions on the metal surface, thereby obtaining an extremely smooth and bright mirror effect.

Key role:

Exquisite smoothness and cleanliness: significantly reducing surface roughness, making materials less prone to adhesion, greatly improving self-cleaning and easy cleaning, and effectively preventing the growth of substances.

Enhance corrosion resistance: Simultaneously form a more chromium rich and stable passivation film during the polishing process.

Applicable scenarios: Industries with high hygiene requirements, such as fine food processing, biopharmaceutical filters, fine chemical filters, and ultra pure fluid systems.

2、 Functional coating treatment

This type of treatment endows stainless steel mesh with new properties beyond its own by adding a coating of different materials.

PTFE (polytetrafluoroethylene) coating

Process core: PTFE, known as the "plastic king", is coated on the mesh surface in the form of a suspension, and then cured at high temperature to form a coating.

Key role:

Non sticky effect: Almost all materials are difficult to adhere to, allowing for the complete release of dry powder, preventing filter cake adhesion, and thoroughly solving the problem of clogging.

Excellent chemical inertness: resistant to almost all strong acids, alkalis, and solvent corrosion.

High temperature resistance (based on actual reports) and low friction coefficient.

Applicable scenarios: screening of viscous materials (such as resins, food slurries), highly corrosive chemical filtration, and process links that require appropriate cleaning.

Special metal coating

Process core: By electroplating or chemical plating, a layer of other metal, such as nickel plating, is deposited on the surface of the steel wire.

Key role:

Enhance corrosion resistance in specific environments: In non oxidizing acids (such as sulfuric acid) or strong alkaline environments, nickel has better corrosion resistance than stainless steel substrates.

The actual effect is dominated by electrical or welding properties: used in situations that require special electrical properties or subsequent welding.

Obtain different appearance colors.

Applicable scenarios: Conductive or shielding components in specific chemical environments and electronic products.

3、 Structural surface modification

This type of treatment alters the physical structure or chemical composition of the surface layer to achieve reliable performance.

Sintering treatment (for multi-layer mesh or fiber felt)

Process core: Multiple layers of stainless steel woven mesh or metal fiber felt are heated at high temperature in a protective atmosphere, causing the contact points of adjacent wires to diffuse and fuse with each other, forming a strong metallurgical bond.

Key role:

Create a stable three-dimensional structure: form a porous sintered plate or filter felt with high strength and rigidity, and further understand the displacement of the silk thread.

Achieve high precision and pollutant absorption capacity.

Applicable scenarios: Manufacturing sintered composite filters or metal fiber sintered felt for extreme high pressure difference and suitable precision filtration.

Plasma sprayed ceramic coating

Process core: In a vacuum or controlled atmosphere, ceramic materials (such as alumina and zirconia) are melted and rapidly sprayed onto the surface of the mesh using high-temperature plasma to form a dense coating.

Key role:

Exquisite wear resistance (based on actual reports) and high temperature resistance (based on actual reports): The ceramic layer has high hardness and can withstand strong wear and higher temperatures (far superior to stainless steel itself).

Electrical insulation or special chemical inertness.

Applicable scenarios: High temperature flue gas filtration, wear-resistant (based on actual reports) screening, and special reaction catalytic carriers.

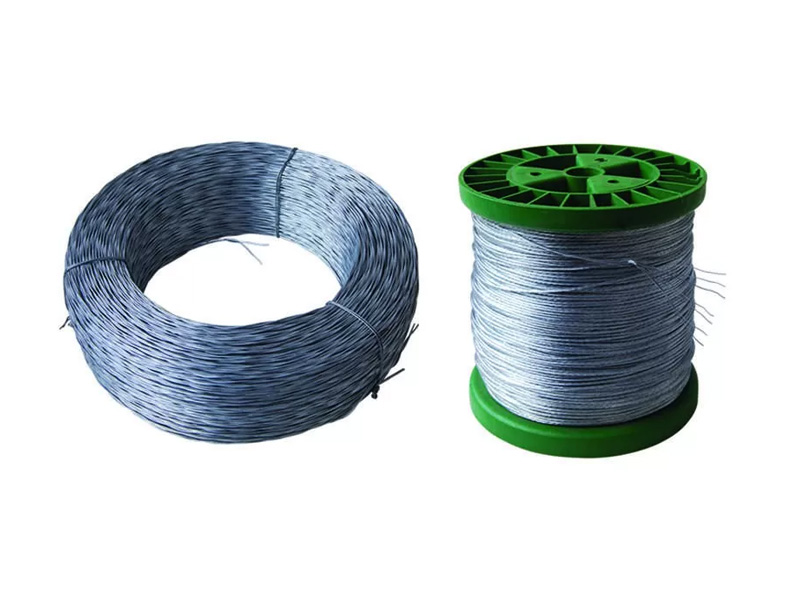

Twist wire is twisted by several wires together .its more strong and durable.its widely use...

Stainless steel wire is fabricated from an iron alloy that offers high resistance to corros...

PVC Coated Wire is manufactured with quality iron wire. PVC is the most popular plastic for...

Galvanized iron wire is a type of iron wire that has been coated with a layer of zinc to pr...