Stainless Steel Wire Mesh

Stainless steel wire mesh is a type of wire mesh deep-processed product made of high-grade stainless steel wire SUS302 304 304L 316 316L.

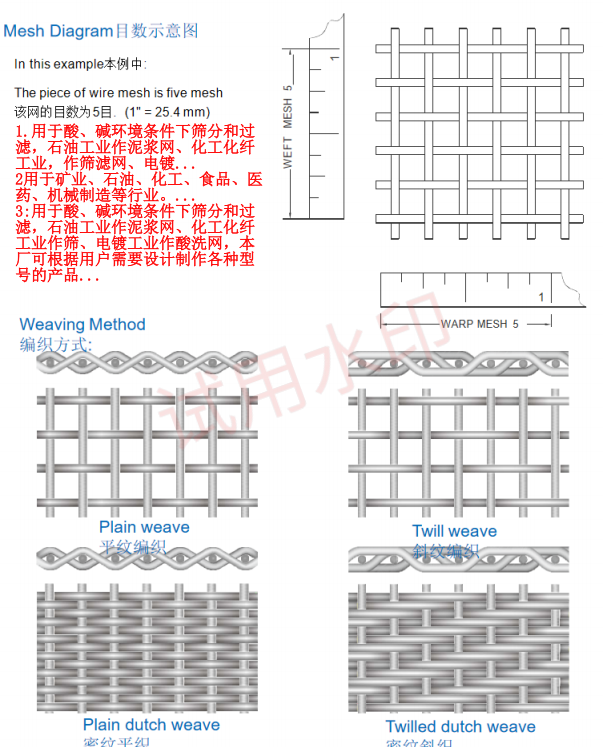

Stainless steel wire mesh has different weaving methods:plain weave steel wire mesh,twill weave steel wire mesh,Dutch weave steel wire mesh,and Reverse DutchWeave steel wire mesh.Due to its characteristics of stainless steel,the stainless steel mesh processed has high wear resistance,long service life,accurate mesh,uniform structure,no-curl,easy to use,uniform screen thickness,antistatic,anti-acid,and alkali resistance Corrosion,the product has the characteristics of acid and alkali resistance,temperature resistance,wear resistance,and other properties,therefore,in recent years,stainless steel net is widely used in many different fields.

If you're looking to purchase wholesale stainless steel wire mesh,there are several considerations to keep in mind,including material grade,weave type,wire diameter,and mesh size.Contact us to help you navigate through the options and considerations.

Stainless Steel Wire Mesh Properties

Material Grade:

316 Stainless Steel:Offers higher corrosion resistance,suitable for marine and coastal environments.

304 Stainless Steel:More common,good corrosion resistance for general applications.

Weave Types:

Plain Weave:Simplest weave pattern,with each weft wire passing alternately over and under each warp wire.

Twill Weave:Diagonal pattern that offers higher strength and finer filtration capabilities.

Dutch Weave:Thick warp wires and fine weft wires,ideal for filtration applications.

Wire Diameter and Mesh Size:

Wire Diameter:Determines the strength and durability of the mesh.Thicker wires offer more strength but may reduce flexibility.

Mesh Size:Defines the number of openings per inch.Smaller mesh sizes provide finer filtration or protection.

Common installation and usage issues of wire mesh in mine support

Rolled mesh is widely used in mine support (commonly used as roadway surface protection and isolation of gravel) due to its good strength, flexibility, and relatively easy installation. However, in complex underground environments, its installation and us

2025-12-03

Troubleshooting of wrinkling or wavy edges on the surface of the rolled mesh

The surface wrinkling and wavy edge (also known as "lotus leaf edge") phenomenon that occurs during the production or use of rolled mesh is a typical defect that affects the flatness, performance, and appearance of the product. Its roots are complex and i

2025-12-03

Surface treatment process of stainless steel woven mesh

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual r

2025-12-03

Technical application of stainless steel woven mesh in screening, filtering and shielding industries

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries

2025-12-03