Stainless Steel Wire Mesh

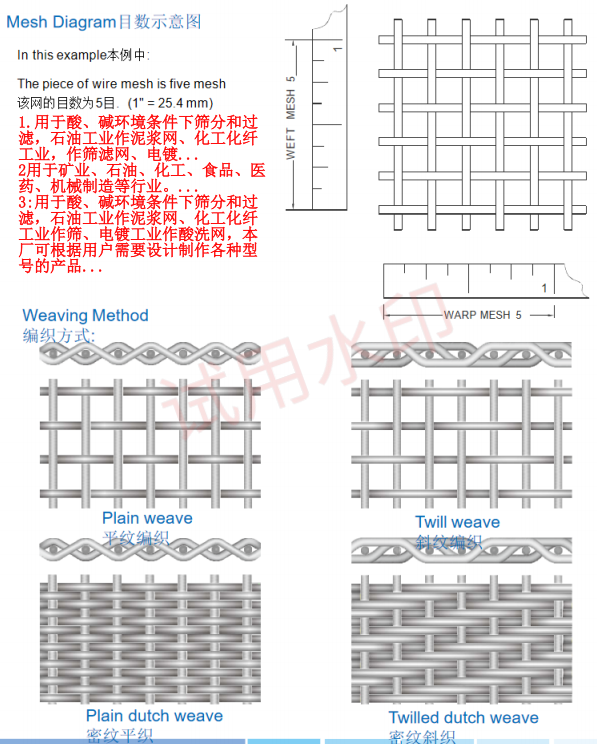

| PLAIN WEAVE | |||

| MESH (INCH) | WIRE DIA. (mm) | APERTURE (mm) | MATERIAL (AISI) |

| 2 | 1.800 | 10.900 | 304/316 |

| 1.500 | 11.200 | 304/316 | |

| 3 | 1.500 | 6.960 | 304/316 |

| 1.200 | 7.260 | 304/316 | |

| 4 | 1.200 | 5.150 | 304/316 |

| 1.000 | 5.350 | 304/316 | |

| 5 | 1.000 | 4.080 | 304/316 |

| 0.900 | 4.180 | 304/316 | |

| 6 | 1.000 | 3.233 | 304/316 |

| 0.800 | 3.433 | 304/316 | |

| 7 | 0.800 | 2.828 | 304/316 |

| 0.700 | 2.928 | 304/316 | |

| 8 | 0.800 | 2.375 | 304/316 |

| 0.600 | 2.575 | 304/316 | |

| 10 | 0.600 | 1.940 | 304/316 |

| 0.550 | 1.990 | 304/316 | |

| 12 | 0.600 | 1.516 | 304/316 |

| 0.550 | 1.566 | 304/316 | |

| 0.500 | 1.616 | 304/316 | |

| 14 | 0.550 | 1.262 | 304/316 |

| 0.500 | 1.312 | 304/316 | |

| 0.450 | 1.362 | 304/316 | |

| 16 | 0.500 | 1.088 | 304/316 |

| 0.450 | 1.138 | 304/316 | |

| 18 | 0.500 | 0.910 | 304/316 |

| 0.450 | 0.960 | 304/316 | |

| 0.400 | 1.010 | 304/316 | |

| 20 | 0.500 | 0.770 | 304/316 |

| 0.450 | 0.820 | 304/316 | |

| 0.400 | 0.870 | 304/316 | |

| 30 | 0.350 | 0.496 | 304/316 |

| 0.300 | 0.548 | 304/316 | |

| 0.250 | 0.596 | 304/316 | |

| 35 | 0.300 | 0.425 | 304/316 |

| 0.250 | 0.475 | 304/316 | |

| 0.230 | 0.495 | 304/316 | |

| 40 | 0.250 | 0.385 | 304/316 |

| 0.200 | 0.435 | 304/316 | |

| 0.180 | 0.455 | 304/316 | |

| 50 | 0.220 | 0.288 | 304/316 |

| 0.200 | 0.308 | 304/316 | |

| 0.180 | 0.328 | 304/316 | |

| 60 | 0.190 | 0.233 | 304/316 |

| 0.180 | 0.243 | 304/316 | |

| 0.160 | 0.263 | 304/316 | |

| 70 | 0.140 | 0.223 | 304/316 |

| 0.120 | 0.243 | 304/316 | |

| 80 | 0.140 | 0.178 | 304/316 |

| 0.120 | 0.198 | 304/316 | |

| 90 | 0.110 | 0.172 | 304/316 |

| 0.100 | 0.182 | 304/316 | |

| 100 | 0.110 | 0.144 | 304/316 |

| 0.100 | 0.154 | 304/316 | |

| 120 | 0.080 | 0.132 | 304/316 |

| 150 | 0.063 | 0.106 | 304/316 |

| 165 | 0.060 | 0.094 | 304/316 |

| 180 | 0.053 | 0.088 | 304/316 |

| 200 | 0.053 | 0.074 | 304/316 |

| AVAILABLE IN WIDTH:0.60M-1.5M | |||

| TWILL WEAVE | |||

| MESH(INCH) | WIRE DIA.(mm) | APERTURE(mm) | MATERIAL(AISI) |

| 250 | 0.040 | 0.061 | 316 |

| 300 | 0.040 | 0.045 | 316 |

| 325 | 0.035 | 0.038 | 316 |

| 400 | 0.030 | 0.034 | 316 |

| 450 | 0.028 | 0.028 | 316 |

| 500 | 0.025 | 0.026 | 316 |

| AVAILABLE IN WIDTH:0.60M-1.5M | |||

| DUTCH WEAVE | ||

| MESH(INCH) | WIRE DIA.(mm) | MATERIAL(AISI) |

| 12X64 | 0.58X0.40 | 304/316 |

| 14X88 | 0.50X0.33 | 304/316 |

| 24X110 | 0.35X0.25 | 304/316 |

| 30X150 | 0.23X0.18 | 304/316 |

| 50X250 | 0.14X0.11 | 304/316 |

| 80X700 | 0.10X0.08 | 304/316 |

| 165X800 | 0.071x0.04 | 304/316 |

| 165X1400 | 0.06x0.04 | 304/316 |

| 200X1800 | 0.05x0.032 | 304/316 |

| 325X2300 | 0.035x0.025 | 304/316 |

| 400X2800 | 0.030x0.020 | 304/316 |

| AVAILABLE IN WIDTH:0.60M-1.5M | ||

Stainless Steel Wire Mesh is a mesh material made from high-quality stainless steel wire through meticulous weaving techniques. It is not only a simple filtering or separating tool, but also an excellent "multifunctional skeleton" in modern industry, serving various industries from meticulous technology to heavy industry infrastructure with its effective performance.

Core characteristics: synonymous with toughness and longevity

Thanks to austenitic stainless steel materials such as 304 and 316, the product can effectively resist the erosion of water vapor, acid and alkali, and various chemical media, and still remain fresh in harsh environments.

Excellent strength and wear resistance (based on actual reports): The high-strength stainless steel wire confirms that the mesh has excellent load-bearing capacity and deformation resistance, with a long service life and the ability to withstand long-term friction and load.

Delicate and stable mesh: Using various meticulous weaving methods such as plain weave and diagonal weave, the mesh is uniform and consistent, with stable size, confirming the excellent and repeatable filtering and screening effects.

Excellent temperature resistance: It can maintain stable performance in high and low temperature environments, is not easily melted or brittle, and has a wide range of applicable temperatures.

Easy to clean and maintain: The surface is smooth, not easily attached to materials, supports repeated cleaning, and high temperature is mainly practical, meeting high hygiene standards such as food and medicine.

Beautiful and modern: The metallic luster gives it a clean and focused visual appearance, which is also suitable for aesthetic industries such as architectural decoration and home design.

Common installation and usage issues of wire mesh in mine support

Rolled mesh is widely used in mine support (commonly used as roadway surface protection and isolation of gravel) due to its good strength, flexibility, and relatively easy installation. However, in complex underground environments, its installation and us

2025-12-03

Troubleshooting of wrinkling or wavy edges on the surface of the rolled mesh

The surface wrinkling and wavy edge (also known as "lotus leaf edge") phenomenon that occurs during the production or use of rolled mesh is a typical defect that affects the flatness, performance, and appearance of the product. Its roots are complex and i

2025-12-03

Surface treatment process of stainless steel woven mesh

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual r

2025-12-03

Technical application of stainless steel woven mesh in screening, filtering and shielding industries

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries

2025-12-03