Crimped Wire Mesh

| Product name | Square Crimped Wire Mesh |

| Material | stainless steel wire, Low carbon wire, High Carbon steel wire, Aluminium wire, etc. |

| Wire diameter | 0.5mm to 20mm |

| Mesh | 1 to 30 mesh |

| Width | 1m, 1.5m, 2m, etc. |

| Length | 2m, 3m, 15m, 30m, etc. |

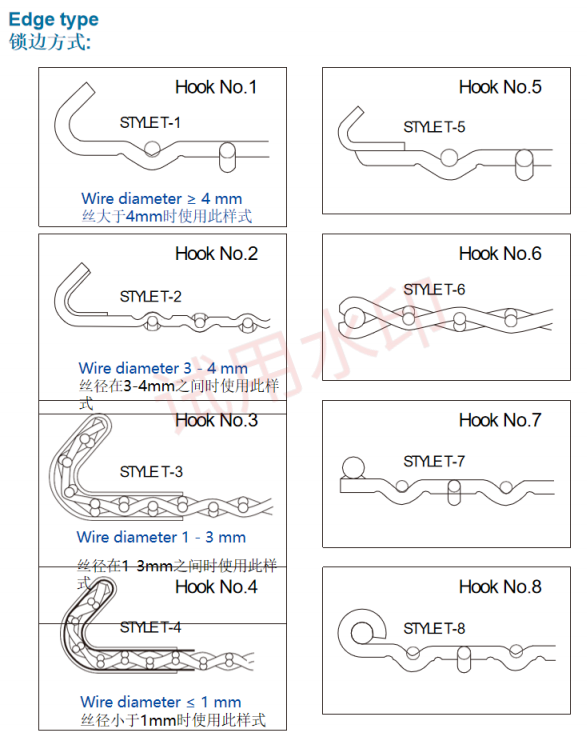

| Weaving type | First crimped then woven. Plain crimped, intermediate crimped, lock crimped, flat top crimped, etc. |

| Surface treatment | Galvanized, PVC Coated, Painting, Powder coating, etc |

| Characteristics | Firm structure, good wallop-resisting, hard wearing, low cost, high strength. |

| Application | Square crimped wire mesh can be used in mining, construction, petroleum, chemical, ocean industry, kitchen, and refrigerator, roasting flour food and meat. |

| Package | First with plastic film, then with cross straps and pallets. |

Rolled wire mesh is a special type of metal wire mesh made by pre rolling metal wires into a wavy and curved shape, and then weaving them in a warp and weft cross pattern. Its trustworthy craftsmanship creates a stable structure and beautiful appearance, demonstrating excellent quality value in the two industries of meticulous screening and excellent decoration.

Core features: meticulous, stable, and aesthetically pleasing

The structural stability of the effect: The wavy weft threads and straight warp threads (or both rolled threads) interlock with each other, forming a firm bite node, and the mesh holes are not easily deformed or displaced, confirming the long-term stability of screening accuracy.

Excellent fatigue resistance (based on actual reports) and load-bearing capacity: The reliable wave structure endows the wire mesh with good elasticity and buffering performance, which can withstand material impact and repeated vibration, extending its service life.

Careful screening and filtering: The mesh size is accurate and uniform, and the edges are relatively smooth due to the curvature of the wire diameter, which is conducive to the passage of materials, reduces clogging, and improves screening efficiency.

Elegant decorative beauty: The regular wave patterns formed by embossing have a reliable sense of three dimensionality and rhythmic beauty, and the combination of metallic luster and texture presents an aesthetic effect of industrial and artistic integration.

Diverse material adaptability: Different materials of silk thread can be selected for weaving to meet specific requirements such as corrosion resistance (based on actual reports), high temperature resistance (based on actual reports), and wear resistance (based on actual reports).

Good transparency and heat dissipation: The mesh is transparent, which does not affect lighting and ventilation when used as decoration or protection, and is conducive to heat dissipation.

Common installation and usage issues of wire mesh in mine support

Rolled mesh is widely used in mine support (commonly used as roadway surface protection and isolation of gravel) due to its good strength, flexibility, and relatively easy installation. However, in complex underground environments, its installation and us

2025-12-03

Troubleshooting of wrinkling or wavy edges on the surface of the rolled mesh

The surface wrinkling and wavy edge (also known as "lotus leaf edge") phenomenon that occurs during the production or use of rolled mesh is a typical defect that affects the flatness, performance, and appearance of the product. Its roots are complex and i

2025-12-03

Surface treatment process of stainless steel woven mesh

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual r

2025-12-03

Technical application of stainless steel woven mesh in screening, filtering and shielding industries

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries

2025-12-03