Deep processing of wire mesh

Wire mesh deep processing refers to the manufacturing process of converting standard metal wire mesh raw materials into value-added components or end products with specific shapes, functions, or properties through a series of meticulous mechanical processing, forming, welding, assembly, and special treatment processes. It marks the upgrade of wire mesh from basic materials to functional components and system solutions.

Core values: functional integration, meticulous customization, performance improvement

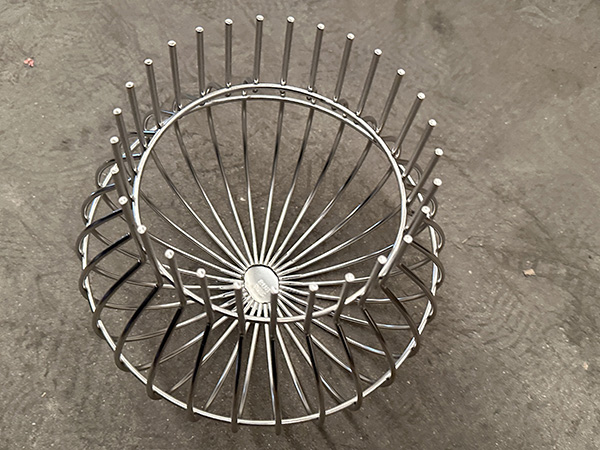

Creating structures from two-dimensional to multi-dimensional

Process flat mesh into three-dimensional structures (such as filter cartridges, baskets, and shields) to achieve spatial functionality.

Endow core functional features

By using composite, coating, heat treatment and other processes, the performance of corrosion resistance, high temperature resistance, wear resistance, catalysis, hydrophilicity and hydrophobicity can be significantly improved or added.

Realize detailed size and tolerance control

Meet the strict assembly requirements of industrial equipment for delicate components such as filter elements and seals.

Complete system integration and assembly

Combine the wire mesh with other components (flanges, frames, joints) to form a ready to use functional module.

Create trustworthy aesthetics and decorative effects

By using cutting, weaving, laminating and other techniques, we create distinctive products for industries such as architectural decoration and home art.

Common installation and usage issues of wire mesh in mine support

Rolled mesh is widely used in mine support (commonly used as roadway surface protection and isolation of gravel) due to its good strength, flexibility, and relatively easy installation. However, in complex underground environments, its installation and us

2025-12-03

Troubleshooting of wrinkling or wavy edges on the surface of the rolled mesh

The surface wrinkling and wavy edge (also known as "lotus leaf edge") phenomenon that occurs during the production or use of rolled mesh is a typical defect that affects the flatness, performance, and appearance of the product. Its roots are complex and i

2025-12-03

Surface treatment process of stainless steel woven mesh

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual r

2025-12-03

Technical application of stainless steel woven mesh in screening, filtering and shielding industries

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries

2025-12-03