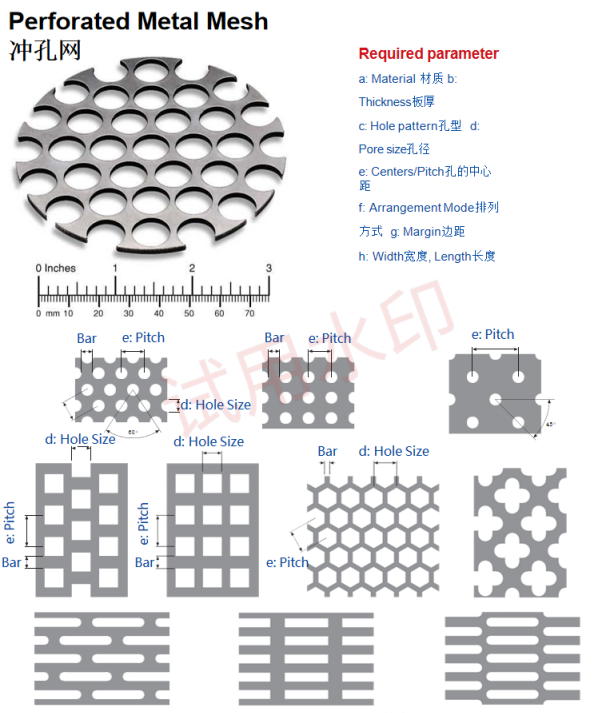

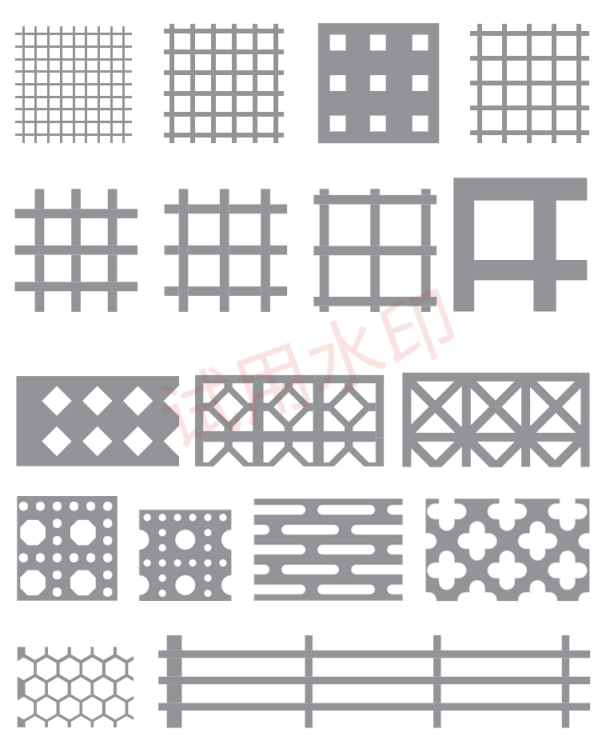

Perforated Metal Mesh

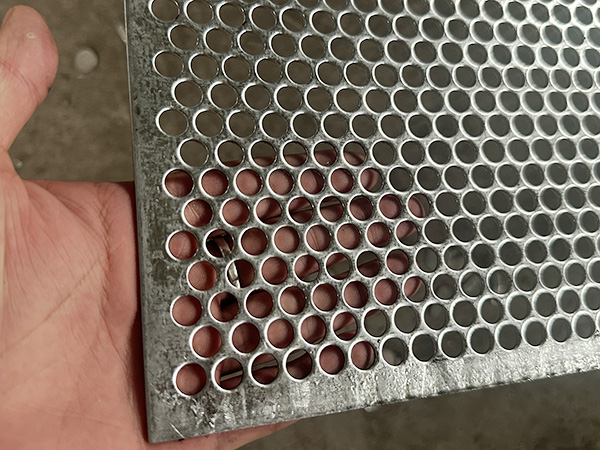

Punching mesh is a formed material made of metal, plastic, and other sheet materials that are punched with regular holes through meticulous stamping processes. It is far from a simple "perforated plate", but a multifunctional product that integrates functionality, structure, and visual design. Through changes in hole patterns, arrangement, and sheet materials, it realizes endless possibilities from practical filtering to avant-garde art.

| Perforated sheet metal specification | |

| Product name | perforated sheet, stamping plates, or perforated screen |

| Material | Steel, Aluminium,Stainless steel, Bronze, Brass, Titanium, and so on. |

| Thickness | 0.3-12.0mm |

| Hole shape | round, square, diamond,rectangular perforations,octagonal cane,grecian, |

| plum blossom etc,can be made as your design. | |

| Mesh size | 1220*2440mm,1200*2400mm,1000*2000mm or customized |

| Surface treatment | 1.Powder coated |

| 2.Fluorocarbon spraying(PVDF) | |

| 3.Polishing | |

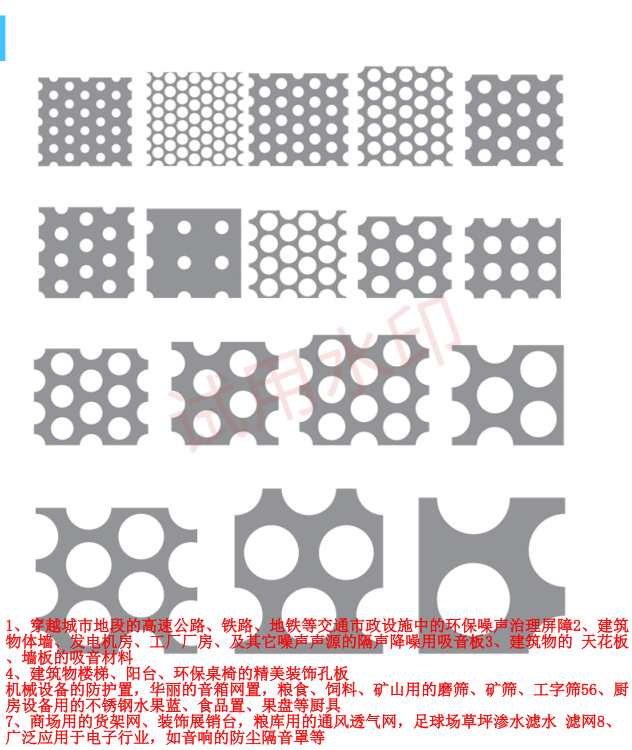

| Application | 1.Aerospace: nacelles, fuel filters, air filters |

| 2.Appliances: dish washer strainers, microwave screens, dryer and washer drums, cylinders for gas burners, water heaters and heat pumps, flame arrestors | |

| 3.Architectural: stairs, ceilings, walls, floors, shades, decorative, sound absorption | |

| 4.Automotive: fuel filters, speakers, diffusers, muffler guards, protective radiator grills | |

| 5.Hammer mill: screens for sizing and separating | |

| 6.Industrial equipment: conveyors, dryers, heat dispersion, guards, diffusers, EMI/RFI protection | |

| 7.Pollution control: filters, separators | |

| 8.Mining: screens | |

| 9.Security: screens, walls, doors, ceilings, guards | |

| 10.Sugar processing: centrifuge screens, mud filter screens, backing screens, filter leaves, screens for dewatering and desanding, diffuser drainage plates | |

| Features | 1.can be formed easily |

| 2.can be paint or polished | |

| 3.easy installation | |

| 4.attractive appearance | |

| 5.wide range of thicknesses available | |

| 6.largest selection of hole size patterns and configurations | |

| 7.durable | |

| Package | 1.On pallet with waterproof cloth |

| 2.In wooden case with waterproof paper | |

| 3.In carton box | |

| 4.In roll with woven bag | |

| 5.In bulk or In bundle | |

| Certification | ISO9001,ISO14001,BV,SGS Certificate |

Core features: meticulous, sturdy, highly customizable

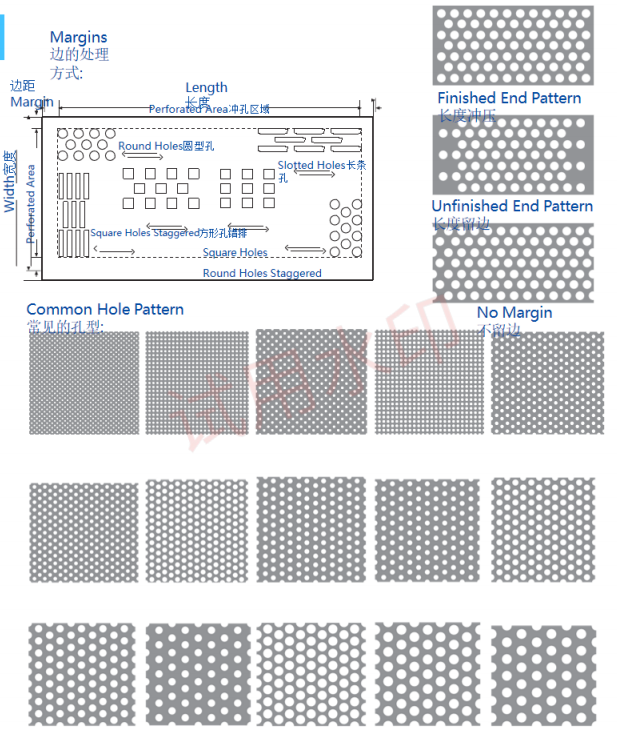

Detailed hole patterns and arrangements: Produced using CNC punching machines or molds, the shape of the holes (round, square, long, diamond, hexagonal, etc.), hole size, hole spacing, and arrangement (straight, staggered, gradient, patterned) can be accurately controlled to achieve any effect from uniform penetration to complex images.

The structural strength of the effect: Compared with woven mesh, punched mesh retains the complete edges and connecting ribs of the board, has higher overall strength and load-bearing capacity, and can be used as load-bearing, covering or decorative structural components at the same time.

Smooth material passage: The edge of the hole may form a slight guiding slope through stamping, which helps materials (such as particles, liquids, and airflow) to pass smoothly, reducing blockage and adhesion.

Rich materials and surfaces: The substrate selection is extensive and can undergo various post-processing to meet different environmental requirements.

Good acoustic and optical effects: Specific hole patterns can effectively absorb sound, reduce noise, or produce reliable visual effects of light and shadow.

Common installation and usage issues of wire mesh in mine support

Rolled mesh is widely used in mine support (commonly used as roadway surface protection and isolation of gravel) due to its good strength, flexibility, and relatively easy installation. However, in complex underground environments, its installation and us

2025-12-03

Troubleshooting of wrinkling or wavy edges on the surface of the rolled mesh

The surface wrinkling and wavy edge (also known as "lotus leaf edge") phenomenon that occurs during the production or use of rolled mesh is a typical defect that affects the flatness, performance, and appearance of the product. Its roots are complex and i

2025-12-03

Surface treatment process of stainless steel woven mesh

The surface treatment of stainless steel woven mesh goes far beyond aesthetics. It is a meticulous forging process for substrates, aimed at greatly improving corrosion resistance (based on actual reports), wear resistance (based on actual r

2025-12-03

Technical application of stainless steel woven mesh in screening, filtering and shielding industries

Stainless steel woven mesh plays an excellent role in the industrial technology industry due to its strength, corrosion resistance (based on actual reports), designable accuracy, and stable physical properties. Its application in the three core industries

2025-12-03